Franz Hofmann: Technologie der Giessereiformstoffe. (Schaffhausen : Georg Fischer AG, 2. Auflage, 1966).

published February 2016

The favorite book of Linda Streckfuss

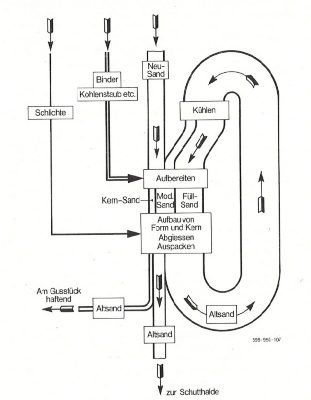

Linda Streckfuss spent a week in 2015 as Scholar in Residence at the Iron Library, where she researched for her bachelor's thesis in industrial engineering. Her thesis deals with the implementation of machine learning methods in the iron foundry of GF Automotive in Singen. What fascinates Linda about her favorite book is the complexity of manufacturing good greensand suitable for casting.