Carl Friedrich Alexander Hartmann (Hrsg.): Atlas zu dem Handbuche der Bergbau- und Hüttenkunde, welcher mittelst Beispielen [...]. (Weimar : Voigt, 1858). 45 Ill. (Kupfertaf.).

published May 2017

The favorite book of Sebastian Haumann

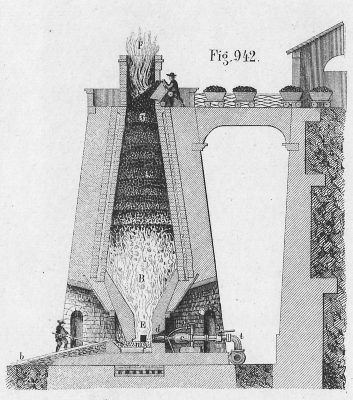

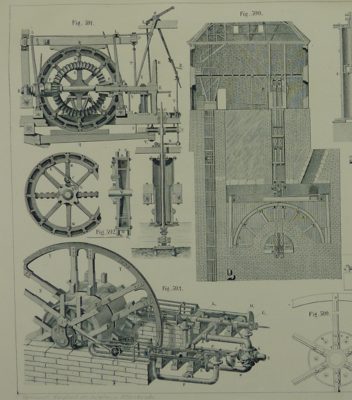

Sebastian Haumann has been engaged in a research project on limestone as raw material of the iron and steel industry in the 19th century - a project that was supported by the Eisenbibliothek's Scholar in Residence Program in 2015. The special feature of his favorite book is that it illustrates the new processes at the blast furnace at a time when the technology was undergoing fundamental changes – and shows the blast furnace "in action".

&crop=(0,40,1275,829))